Solar Thermal

Current Solar Heating Syatems:

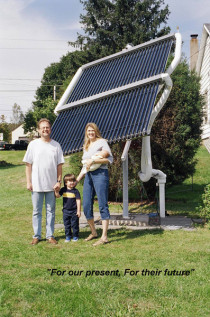

Heating Systems: 200sqft active solar hot air collector, 70sqft. evacuated tube tracking liquid collector, all integrated with a 3000 lbs water storage tank. Backup

DHW heat is a 40 gallon electric water heater. The two 4500W elements have been re-wired in series to drop down the total load for BOTH of them to 2250W. This is part of the load "flattening" I have

done to accomidate the off grid capabilities when on inverter backup power. Reducing peak loads is an important part of energy efficiency and management. At this time, none of the evacuated tube or

hot air collector heat is used in direct connection for the SAHP geo assist. I have one more evacuated 60 tube ground array to bring on-line before I directly heat the EW for the geo heat pumps.

PLEASE keep in mind that allot of the photos below show the history and evolution of the solar systems through time.

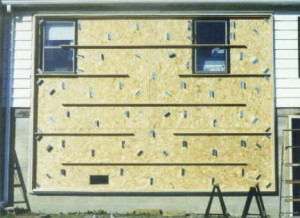

The hot air collector pictured, was the first project chosen for the homes energy makeover. I chose this as the first, because the impact to the other areas of the

house were minimal, yet the effect on oil usage would be large. I decided not to use glass as the glazing for several reasons. Weight and danger from breakage due to the size of the collector and its

location, were two main factors. Another was that I wanted something more transmittive than glass. Ultimately I chose Teflon. Its durability under sunlight, "zero weight", extreme clarity to the suns

energy (96%+), were the major benefits. By using a film type glazing, the support structure for the glazing mounting would virtually disappear. The aluminum collector itself is comprised of three

sheets of corrugated Aluminum 16’ x 4’ running horizontal. When the collector is finally complete, it will have three layers of Teflon, with three separate air spaces. At present it has only one.

Even with three layers, 85% solar transmission will be maintained. Currently the output air maximum is around 140 deg’s F at a flow rate of about 600 to 800 CFM.

The size of the hot air collector was determined by the general rule of thumb of 1 sqft of collector for each 10 sqft of heated floor space. Approximately 2000 sqft to

heat, therefore 200 sqft of collector. Since the photo above, a concrete patio has been added. During the heating season, which is when the hot air collector is active, I put aluminum reflectors on

the patio which bounce extra solar radiation onto the collector. The gains are about 10 to 15 degrees in output air temp. The collector did not have any storage initially tied to it. This was to come

with the introduction of a year round liquid collector. The goal was always to put a 3.5 meter parabolic tracking collector for the liquid part, coupled with the appropriate size water storage. But

the parabola project was not going to be complete, perhaps for a long time, so I opted for a simple 4’ x 8’ copper flat plate collector. This would allow the whole system to be completed.

Operationally, all testing could be completed and all "bugs" could be eliminated. The benefits of storage could start to be realized, although the heat values into storage would of course be much

less than with the dish unit.

The hot air collector worked so well, even with its single layer of Teflon, that it was necessary to extract some excess heat from it once the liquid storage and

liquid system came on line. This was done with the addition of a heat exchanger between the air collector and the blower. In the long run, the extraction of "extra" energy from the hot air collector

would not be necessary. When the basement level was complete from an insulation and drywall perspective, about 50% to 75% of the hot air from the collector would be shot down there directly

eliminating upstairs overheating. Secondly, the box temperatures are expected to average in the 100+ range most of the time when the dish comes on line, that only a minimal amount of heat be gained,

not enough to justify the pump energy used for the extra circulation.

The tracking evacuated tube collector which has been on line since 9/21/2004, can be viewed as an intermediate project, replacing the 4'x8' flat plate collector. Box

tempatures are already substantially higher. This year, Winter 2004-2005 I am not using reflectors and I am trying to get the extra Teflon glazings in place, finishing the original design

concept.

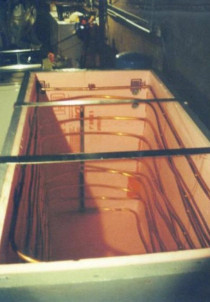

The water storage box pictured, is made of 1-1/2" plywood (2 - 3/4" material laminated together) coated inside with epoxy paint and fiberglass on all seams. It stands 4’ tall, about 5’ deep and 30" wide. The exact inside volume is 46.32 cubic feet @62 pounds per cubic foot is 2871 lbs. With some copper, bricks and steel inside I round it off to 3000 lbs. of water or 3000 BTU’s per deg. F. change. The box has 120 feet of ½" copper tubing which serve as a heat exchanger to put heat into the box as well as take it out. When the exchanger fluid is in heat delivery mode, it flows from the top down. When in extraction mode, it flows from the bottom up. This gives the exchanger a degree of counter flow functionality, since the box is always warmer at the top than at the bottom.

The 20 gallon stainless steel tank in the second photo sits in the center of the box in an upright position. Well water on the way to the oil fired water heater, flows into the bottom fitting of the stainless tank and exits the top. Having a "cold" source in the center of the box, and the hot coils on the sides of the box, serves to set up a convection loop which further increases heat transfer efficiency.

The third photo shows the completed box. With the 1" extruded polystyrene insulation (R5) inside and the 1" fiberglass insulation (R4) on the outside, plus a little R value from the wood itself, the bottom and sides are rated at R10 total. The top is 3" of foil faced polyurethane (R22). Approximately 15 gallons of ethylene glycol (regular car antifreeze) was added to the water in the box for bacteria control. This also doesn’t hurt when it comes to corrosion resistance. The Brock oil fired water heater sits to the right of the box, the Rheem air handler over the top, and the 275 gallon oil tank to the left. The box was designed to fit right in the space created by those three system pieces. The air expansion tank, pressure gauge, fill ports (in and out), and some of the plumbing are located on the front end of the box. The Rheem air handler above, was fitted on the front with a Snowmax heat exchanger, which is how the heat from the box is transferred to the air on its way to the main heating coils for the homes space heating. The warmer the air before it hits the main coils, the less the oil burner runs. This setup reflects the systems before the geo was in place. Currently, the solar box heat preheats DHW only.

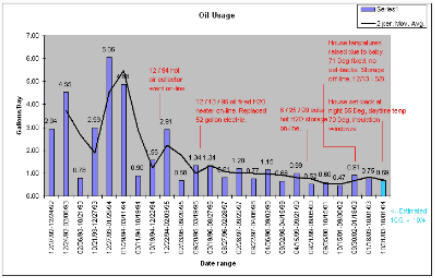

The oil fired water heater shown above, is a Bock 32 gallon, with a .75 GPH nozzle installed in the burner. The heater is tied to a Rheem air handler which provides the space heating for the home. A Snowmax heat exchanger was placed on the front of the air handler to preheat the air on its way to the main heat exchanger. The fluid running through the Snowmax is solar heated from the box water storage. A 20 gallon stainless steel tank within the box (see storage picture) preheats the well water before it goes to the O.F.H.(oil fired heater). The clock shown in the photo sitting on top of the heater, only runs when the oil burner is running. It is reset everyday, so the total oil burner runtime can be recorded each day. This piece of data coupled with storage temps., provides much of the information for the solar systems effectiveness (see detailed graphs) in reducing oil and electric usage. The O.F.H. ‘s plumbing is such that it can be isolated for cleaning or failure with the twist of two stainless steel ball valves. The box water storage also has the same capability. The entire system is designed in such a way that the failure or maintenance of one major part does not effect another, so you always have a source of heat. The vent pipe for the O.F.H. has a Magic Heat heat exchanger in the stack pipe which extracts heat from the waste gases. The chimney temp usually is between 150 and 300 degs. F., which is "cool" for an oil burner.